پیشرو در صنعت ساخت تابلو

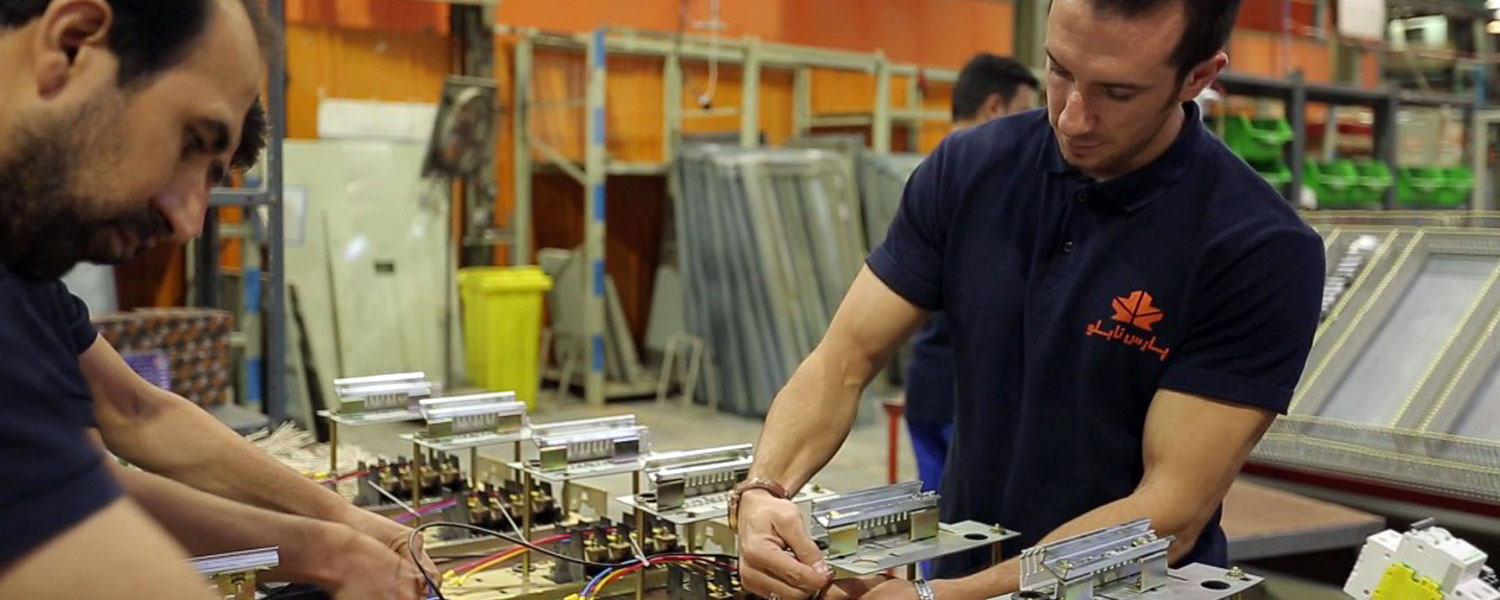

محصولات پارس تابلو صنعت، نخستین و با قدمت ترین برند شناخته شده محصولات برقی در گروه BLUE&P محسوب میشوند که با بیش از نیم قرن تجربه موفق در ساخت و تولید انواع تابلو برق صنعتی ، بانکهای خازنی و پست های کامپکت در ایران و خاورمیانه، افتخار خدمت رسانی داشتهایم. ما در شرکت پارستابلو صنعت با بهکارگیری تجهیزات مدرن و مرغوب، آزمایشگاه کنترلی کیفی پیشرفته و بهرهمندی از دانش کارشناسان خبره صنعت برق، توانسته ایم با تولید و فروش تابلوبرق های صنعتی در تراز رقبای جهانی، امروز بهعنوان سازنده پیشرو و معتبر تابلوسازی در صنایع برق ایران شناخته شویم.

شبکه های توزیع برق فشار متوسط و ضعیف، نیروگاه های تولید برق، صنعت پتروشیمی و صنایع وابسته، صنایع فولاد و سیمان، معادن، نفت و گاز، راه آهن و فرودگاه ها، پروژه های زیرساخت شهری و بیمارستان ها، پارک ها و مزارع بادی، صنایع کشاورزی و دامپروی، تاسیسات صنعتی و ساختمان های بزرگ، مراکز کنترل، کنترل موتور و تابلو های برق روشنایی، بخش عمده مشتریان خرید تابلو برق صنعتی و تجهیزات برق پارس تابلو صنعت را شامل میشوند.

سابقه طولانی در نوآوری و استفاده از تکنولوژی های روز دنیا به منظور مرتفع نمودن نیاز های مشتریان

پارس تابلو صنعت مجموعه کاملی از خدمات مهندسی، تدارکات، ساخت و راه اندازی را برای اجرای موفق پروژه ها فراهم آورده و با بهره گیری از سوابق در تحویل پروژه ها و تجربیات بدست آمده در زمینه مدیریت تغییرات، ریسک، زمان و هزینه در جهت رفع تمام نیازها اعم از از پروژه های کوچک تا توسعه پروژه های عظیم و ملی برای مشتریان ایجاد اطمینان می نماید.پارس تابلو با اتکا به توانایی های خود در حوزه های مختلف و بهره گیری و پیاده سازی ایده های خلاقانه توسط سیستم تحقیق و توسعه خود ، آماده ارائه راه حلهای جامع در صنعت برق می باشد.

افتخارات و گواهینامه ها

افتخار داشته ایم با این سازمانها و شرکتها همکاری کنیم

(همکاری با شما افتخار ماست)